Attention should be paid to the maintenance and speed of the pipe bending machine

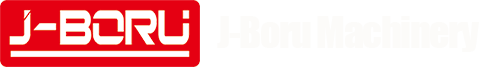

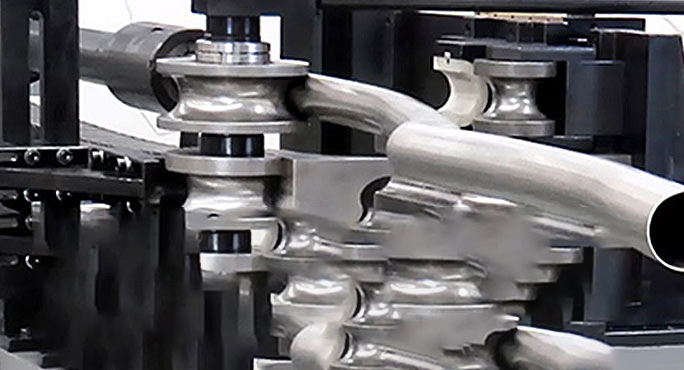

During the operation of the pipe bending machine, all components of the machine can be maintained under harsh environmental conditions (such as rainwater), improper operation and misoperation, and overload. The bending function is used to inspect the appearance of the anti-corrosion main pipe for oil stains, dents, bends, wrinkles in the anti-corrosion layer, unclear or incorrect identification of the anti-corrosion number and pipe number, scars, mechanical damage, and other visual defects, and to keep inspection records. All systems of the pipe bending machine are suitable for operation in an environment of ± 40 ℃ and 0-100% humidity. The pipe bending machine is suitable for local use at altitudes of 0-3000m. Before operating the pipe bending machine, a suitable workplace should be selected. The site should not only be satisfied with the stacking of straight pipes and bent pipes, but also ensure that the pressure of the equipment can be accepted on the ground.

The primary impact of the bending speed of the pipe bending machine on the forming quality is:

The speed is too fast, resulting in a flat curved part of the catheter that does not meet the required roundness, causing the catheter to crack or break; If the speed is too slow, it may cause wrinkling and slipping of the clamping block of the catheter, and larger diameter pipes may easily cause sinking of the curved part of the catheter. For many experiments on these two CNC pipe bending machines, it is advisable to determine the bending speed of the conduit as 20% -40% of the maximum bending speed of the machine.

Maintenance methods for elbows and bends

1. Long term stored elbows and bends should be inspected as scheduled, and the exposed processing surface should be cleaned regularly to eliminate dust and dirt. They should be stored neatly indoors in a ventilated and monotonous area, and stacking or outdoor storage is prohibited. Regularly adhere to the monotony and ventilation of elbows, maintain the cleanliness and regularity of equipment, and store according to precise storage methods.

2. When using equipment, the elbow and bend pipe can be directly installed on the pipeline according to the connection method, and the equipment can be installed according to the direction of use. In general, the equipment can be installed in any direction of the pipeline, but it needs to be easy to check for operation. Be careful that the flow direction of the cut-off elbow medium should be upward from the bottom of the longitudinal valve disc, and the elbow elbow can only be installed horizontally. Attention should be paid to the sealing of the elbow during equipment installation to avoid leakage and affecting the normal operation of the pipeline.