Expert interpretation of the application areas and key points of manual pipe cutting machines

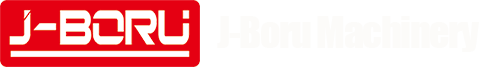

A pipe cutting machine is a specialized machine tool suitable for cutting the waste pipe heads at both ends of seamless steel pipes in large quantities, automatically or semi-automatically. Its annual steel pipe cutting capacity is 400000 tons. The end face of the cut pipe can automatically chamfer the outer corner, inner corner, or cut a large groove. This pipe cutting machine has the characteristics of high stiffness, high power, high automation level, and high production efficiency, and is a necessary equipment for producing seamless steel pipes. The working process of the pipe cutting machine is controlled by the hydraulic system. Due to the heavy load and frequent action of the bracket cylinder in the original hydraulic balance circuit of the pipe cutting machine, the energy loss is too large. Excessive energy loss is not only a waste, but also causes a series of problems such as increased oil temperature, increased leakage, accelerated oil aging, and affecting the quality of cut machining. For this purpose, an analysis was conducted on the hydraulic balance circuit of its bracket cylinder, and a new type of hydraulic balance circuit that can recover the potential energy of heavy objects and make use of it was proposed.

The cutting of pipes is usually done using electric pipe cutting machines and saws. When using an electric pipe cutting machine for operation, a power supply is required, and the working space is large, which is prone to generating electric sparks and noise; Sawing operations have low efficiency and long cycles, and cannot be used on construction sites. Therefore, the use of electric pipe cutting machines and saws in pipeline construction and maintenance operations is limited.

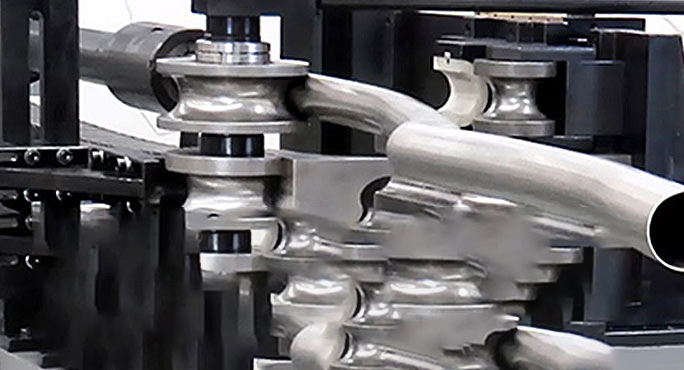

Manual pipe cutting machine is a tool that achieves pipe cutting through its own rotation. It is mainly suitable for cutting steel and cast iron pipelines with different diameters, media, and temperatures, and can be widely used in pipeline construction and maintenance operations. Manual pipe cutting machines are widely used in pipeline construction and maintenance operations abroad. Importing manual pipe cutting machines from abroad not only has high prices, but also long delivery times, which brings inconvenience to future maintenance. So, we should choose as many domestic * manual pipe cutting machine series products as possible

Key points for the application of manual pipe cutting machines

Select according to the diameter of the cut pipe; When fixing the manual pipe cutting machine, the tension should be moderate to ensure good contact between the four cutting blades and the outer wall of the pipe; When performing cutting operations, the manual pipe cutting machine should be pulled in one direction using a handle, and the force should be even; After each half turn of the manual pipe cutting machine, the nut can be tightened with a crank to feed.

(1) The manual pipe cutting machine has a simple structure, small volume, and convenient operation, and can be suitable for cutting operations of pipelines with different diameters, media, and temperatures.

(2) The homework space is small, allowing for the cutting of large-diameter steel and cast iron pipes in limited space. When cutting a 200mm pipe, only 100mm of operating space is needed around the pipe; When cutting a 500mm pipe, only 200mm of operating space is needed around the pipe.

(3) No power supply is required during homework, with low noise and safe use. It can be cut in ditches, underwater environments, and explosive environments with low noise, especially suitable for use in outdoor environments without power supply.

(4) Cutting is labor-saving and fast, and the cut shape of the pipe is regular after cutting.

In summary, the following conclusions can be drawn:

(1) In the development process of manual pipe cutting machine, key issues such as frame processing, material selection of cutting tools, and heat treatment process were solved. Its technology has reached the same level as foreign counterparts, filling the gap in China.

(2) Manual pipe cutting machines have many advantages and can be widely used in the construction and maintenance of steel and cast iron pipelines.

(3) In the maintenance operation of the Northeast oil pipeline, the manual pipe cutting machine has been used on site with good results, reducing the labor intensity of workers, improving the quality of the project, and having considerable economic and social benefits.

(4) At present, it is the peak of the second construction of domestic pipelines, and multiple new oil and gas pipelines will be built. At the same time, the existing oil and gas pipelines also need to be continuously maintained, so the market prospects of manual pipe cutting machines are broad.