What is the impact of CNC pipe bending machine on the industry?

According to professional analysis, the high-end pipe bending machine market in China has always been dominated by companies from the United States, Japan, and Germany, while the mid-range market is mainly divided by Taiwan pipe bending machines, mainland pipe bending machines, and South Korean pipe bending machines. German pipe bending machines can be called industry giants regardless of their performance or manufacturing process. If they enter the mid-range market, it will have a significant impact on non German enterprises. Chinese domestic pipe bending machines are mainly concentrated in the low-end market. Although Chinese enterprises are gradually moving towards the mid-end market, the mid-end market is still mainly made in Taiwan and South Korea.

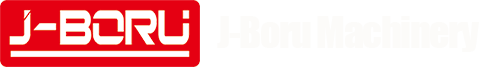

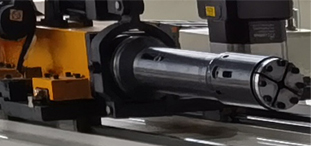

Nowadays, in most domestic enterprises, traditional manual cutting methods are mostly used for sheet metal processing. As a technological product in the mechanical industry in the new century, CNC pipe bending machines are widely used in industries such as steel, mechanical manufacturing, and shipbuilding. The significance of CNC pipe bending machines for mechanical equipment is equivalent to an industrial revolution. In the increasingly fierce market competition of mechanical equipment, CNC pipe bending machines, as high-tech products, not only improve work efficiency. CNC pipe bending machine is a part of mechanical equipment and has also had a profound impact on the mechanical equipment industry.

CNC pipe bending machines have obvious technological advantages compared to manual cutting machines. Nowadays, CNC pipe bending machines generally use CNC systems from Shanghai Jiao Tong University or Beijing Startech. The main advantage of this CNC cutting machine is that it can intelligently cut without programming. It only needs to import the converted CAD graphics of the used nesting software to work on its own and automatically nesting. Compared to manual cutting, it has high technical requirements and slower work efficiency. CNC pipe bending machines can greatly reduce employee technical costs, improve work efficiency, and save materials. From a medium to long-term investment perspective, CNC pipe bending machines are generally chosen. The CNC pipe bending machine, as the main equipment for thick plate cutting, is of great significance in the field of machinery.